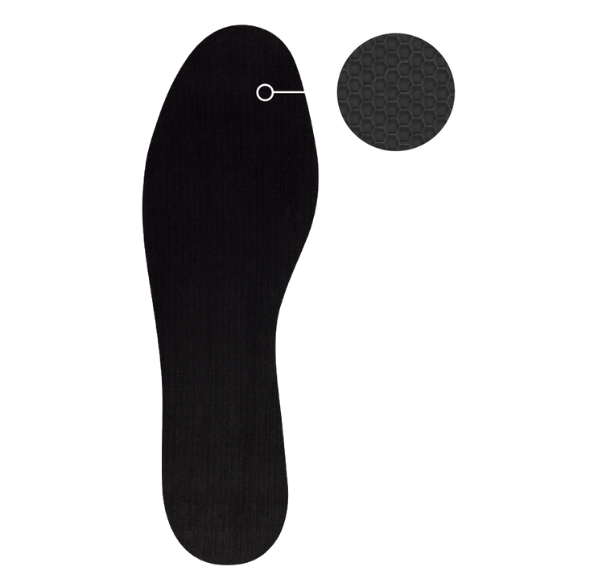

Formed by crystalline micro-cells which is part of the big rubber family.

NOENE® is an innovative vibro-absorbent elastomer

Thanks to the selection and combination of different involved element, a long and complex manufacturing process give birth to a extraordinary performance material, in which specifications and design play a fundamental role in the performance of the application.

Its specificity makes it an irreplaceable product: there are no alternative solution to the noene material on the market as it is the only one in the world that, starting from 1 mm thin, has these characteristics.

Materials such as RUBBER, E.V.A. and derivatives have excellent characteristics of elasticity and dampening to ergonomically accommodate the foot and distribute loads evenly.

NOENE® does not change based on the frequency of the impact it receives, ensuring maximum protection even if the material to which it is applied reaches its maximum level of compression due to crushing or deformation.

Its main feature is its visco-elasticity, which bestows to the product the unparalleled ability to absorb and disperse the negative energy of shocks and vibrations.

The graphs created by DROP TEST show the force that a steel ball in free fall transmits to a load cell.

The results show that at the same drop height of the ball and for the same amount of material (RUBBER, E.V.A, NOENE®), NOENE®, fully absorbs the Negative Energy

generated by the Shock (there are no rebound effects) and reduces the impact on the

bottom surface of the measuring instrument. (N=force peak caused by the impact expressed in Newton).

Materials such as RUBBER, E.V.A. and derivatives have excellent characteristics of elasticity and dampening to ergonomically accommodate the foot and distribute loads evenly.

NOENE® does not change based on the frequency of the impact it receives, ensuring maximum protection even if the material to which it is applied reaches its maximum level of compression due to crushing or deformation.

Its main feature is its visco-elasticity, which bestows to the product the unparalleled ability to absorb and disperse the negative energy of shocks and vibrations.

The graphs created by DROP TEST show the force that a steel ball in free fall transmits to a load cell.

The results show that at the same drop height of the ball and for the same amount of material (RUBBER, E.V.A, NOENE®), NOENE®, fully absorbs the Negative Energy

generated by the Shock (there are no rebound effects) and reduces the impact on the

bottom surface of the measuring instrument. (N=force peak caused by the impact expressed in Newton).

NOENE® ABSORBS and DISSIPATES up to 96% of the negative energy generated by shocks and vibrations with a thickness of only 1 or 2 mm.

NOENE® effectiveness has been proven by scientific studies and lab tests at the Biomechanics Institute of Valencia and Politecnico of Milan.

NOENE® is manufactured in Switzerland meeting high quality criteria in compliance with ISO 9001 and ISO 14001 standards for environmental respect.

The APMA Program (American Podiatric Medical Association) recognizes products that have been found beneficial to foot health and of significant value when used in a consistently applied program

of daily foot care and regular professional treatment.